What do you do as a tool mechanic?

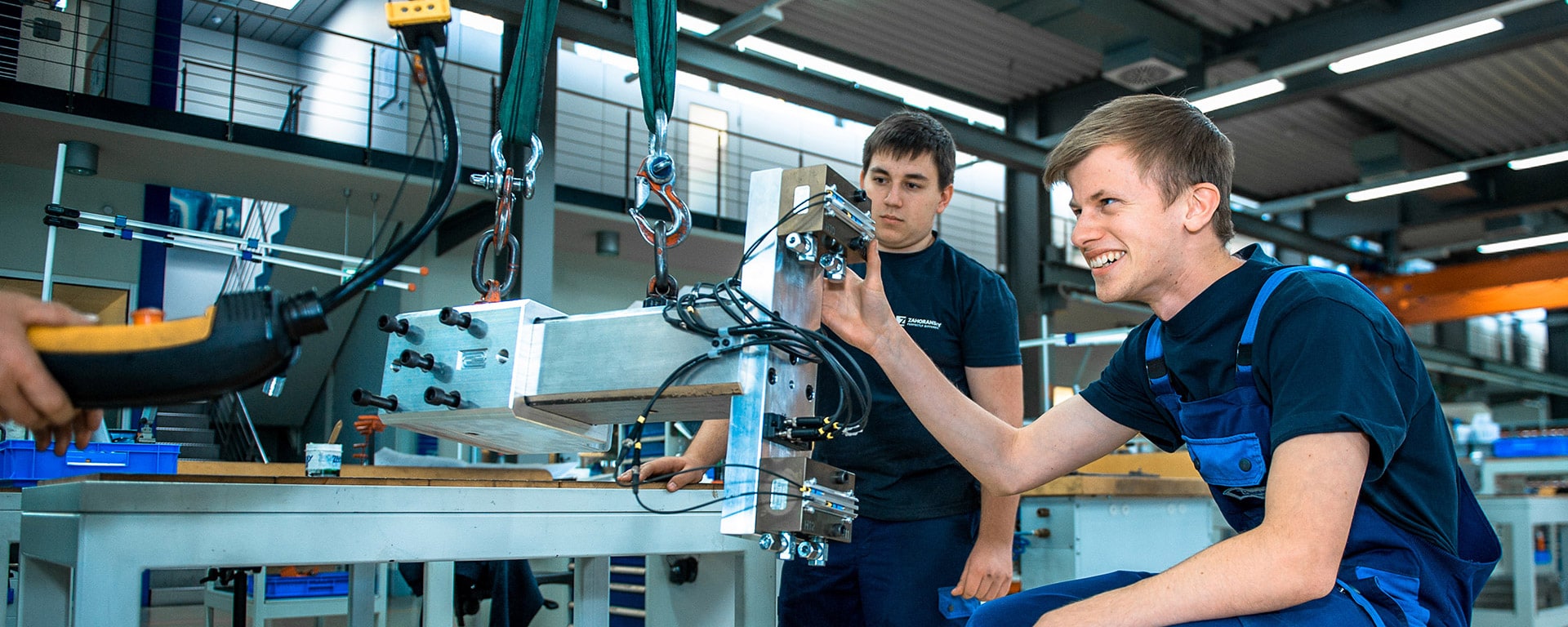

Are standard hammers and screwdrivers too boring for you? Then a dual apprenticeship as a tool mechanic is the right thing for you. Because special tools are needed to manufacture car or mobile phone parts. It is precisely these special tools that you will build as a tool mechanic. You drill, turn and grind until each individual part corresponds exactly to the specifications. Some steel parts have to be hardened. To do this, you heat them to over a thousand degrees – a hot affair. Of course, you don’t do this by hand. Instead, you programme machines to carry out the work steps for you. Of course, you need a lot of knowledge about different raw materials, what properties they have and which materials can be processed and used in which way. Finally, you will build special tools step by step, which will later produce components with millimetre precision. You will also maintain and inspect the tools within your company.

Where are you needed?

As a tool mechanic, the tool and mould making workshops are your home. Here you can let off steam and produce special tools for a wide range of industries. This guarantees variety, as every industry and every product has its own requirements. But there are also opportunities in other areas. Companies that produce components in series also need tool mechanics. This applies to many companies in mechanical engineering, but also in the electrical and automotive industries. If you are primarily interested in small components, you should look for companies in the precision engineering and medical technology sectors. They need specialists like you to build the special tools needed to manufacture the smallest components.

What should you bring with you?

Your future training company usually wants you to have at least an intermediate school-leaving certificate. But above all, it is important that you are enthusiastic about technology and talented with your hands, then you will have a good chance of getting a job even with a secondary school leaving certificate. This also means that you are not afraid to get your hands dirty and that you like to get stuck in. If you also have an interest in maths and physics, you are perfectly suited.

Your apprenticeship at a glance

- 3.5 years

- Theory at vocational school, practice at the training company

- Training content: You will learn to read technical documents and put them into practice so that you can manufacture tools precisely according to the specifications. You will be taught various machining processes and practise materials science. The assembly and disassembly of tools are also part of your training programme.

- After your dual training, you can specialise further and, for example, take the examination to become an industrial foreman specialising in metal. You may also be interested in studying, for example mechanical engineering.If you are very interested in the technical part of your profession, you have the opportunity to continue your training to become a technician specialising in metal technology.